We started American Heritage Flooring with a simple goal: manufacture engineered flooring using American Hickory, the hardest and most durable of North American timbers, and finish it to-order right here in Southern California.

With American Heritage we have created an accountable, transparent supply chain from forest to finish. We have kept the harvesting of the hardwood timber here in the USA, where responsible, sustainable hardwood forest management is the norm. What’s more, every floor is finished to-order in our Southern California finishing plant, under the watchful gaze of one of the strictest pollution control agencies in the world: California’s South Coast Air Quality Management District. With no added Urea Formaldehyde and no VOCs, you can be assured that the air quality inside you home will not be affected by the finish on your floor. And we are doing it all at a remarkably affordable price.

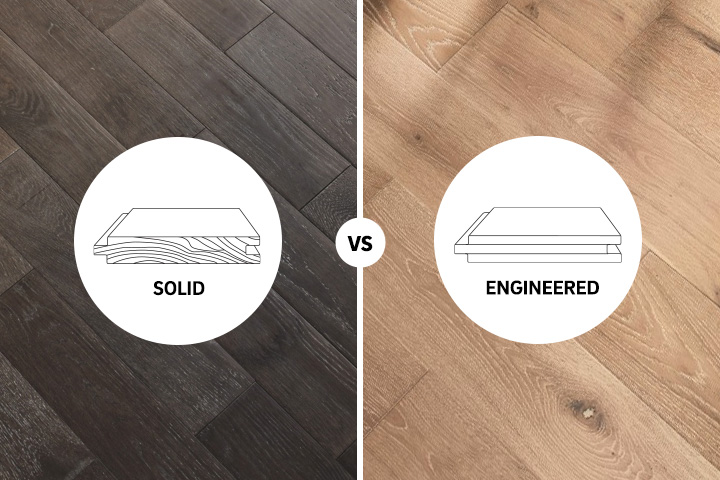

SOLID VS ENGINEERED VS LAMINATE: WHAT’S THE DIFFERENCE?

When investing in a new floor, many homeowners are faced with a choice between hardwood and laminate. The difference between these two types of floors can be confusing at first, which is why we put together a simple guide that compares hardwood against laminate, highlighting the pros and cons of each floor type in terms of appearance, durability, longevity, ease of maintenance and repair, and eco-friendliness.

The Fundamentals

When discussing Laminate, it’s helpful to start out by defining what laminate is not: laminate is not real wood. Laminate is a multi-layer synthetic flooring product. It is designed to imitate the appearance of real wood, but it is not. The core layer of laminate flooring is manufactured primarily from melamine resin and fiber board material. The top layer has an imprinted textured image (a photograph) made to look like real wood.

Both Engineered and Solid hardwood flooring are real wood.

Engineered hardwood flooring is a type of wood floor that consists of several wood or plywood layers. Bottom and middle layers are manufactured from cross-laid solid wood or plywood planks. The top layer consists of a solid sawn wood layer, called a wear layer or a lamella, often stained and prefinished in factory setting. Engineered hardwood flooring can be glued-down or nailed-down, and the added stability of the engineered construction makes engineered construction especially suitable for very wide planks (7”+).

Solid hardwood flooring planks are produced from single pieces of wood, can be purchased unfinished or prefinished. Solid hardwood floors can only be nailed-down, so installation over a concrete slab is made quite difficult (a plywood subfloor must be added).

In essence, while solid or engineered hardwood flooring is manufactured from real wood and preserves the unique textured grain and appearance of natural wood, laminate flooring is only an imitation. Although some types of high quality laminate floors might look like real wood, there are far more differences between these products than what initially meets the eye.

Appearance and Aesthetics

In terms of aesthetics, the difference between hardwood and laminate floors is glaringly obvious. Real wood is characterized by tremendous texture variation of the wood grain, which is why no two planks of hardwood flooring, whether solid or engineered, appear exactly alike. In laminate flooring, pre-designed patterns that imitate the look of wood texture, are imprinted onto the floor surface. For this reason, identical patterns are repeated on average every 5 boards.

Although in appearance some high-quality laminate floors may look like real wood, repetition is unavoidable, as uniqueness of an authentic wood is impossible to replicate.

Durability

Durability of any flooring surface largely depends on intensity of foot traffic, as well as adherence to manufacturer recommendations in regard to care and maintenance of the floor.

Outer layer of most laminate floors is manufactured by bounding melamine resins and aluminum oxide at high heat and extreme pressure. The resulting floor surface is often harder than that of natural wood. Most laminate floor surfaces are highly resistant to moisture damage, staining and fading. In fact, many reputable laminate flooring manufacturers offer 10 to 25-year warranties on finish.

Durability of an authentic hardwood floor varies depending on finish, manufacturer and maintenance practices. Solid or engineered hardwood floors can be refinished, renewed and repaired fairly easily, often without the need to replace planks or even the entire floor, as is the case with damaged laminate flooring. For example, in the event that an oiled wood floor plank is damaged, it can be fixed by manually sanding down the affected area, then simply applying more stain and oil. With laminate flooring, simple DIY spot repairs are not possible.

On some types of hardwood floors, such as those with wire brushed and oiled finishes, minor surface dents and scratches seamlessly blend in with the existing look, emphasizing the unique appearance and depth of wood texture. Once scratched or chipped, laminate flooring surfaces will show the damage.

Moisture

Wood is an organic, “breathing” material that responds to fluctuations in humidity and temperature. For this reason, solid and engineered hardwood floors should be installed in interiors where humidity levels are monitored and kept at 35-55% solid and engineered floors. In warm and humid climates, such as Florida, hardwood flooring that is multilayer or engineered is preferable over solid.

Laminate floors have high resistance to moisture and are often used for kitchens, bathrooms, and basements. Nevertheless, it’s important to carefully read the manufacturer warranty and recommendations in order to avoid costly mistakes.

Ease of Repair

Laminate flooring does not repair easily. In floating laminate flooring – one that’s installed by snapping individual pieces together and laying them without glue – damaged planks can be removed and replaced. If laminate flooring was installed using glue-down method, floor repair becomes very difficult. Laminate cannot be sanded or refinished. Even if damaged planks are removed and replaced, there is high probability that the new pieces will not properly match the rest of the floor due to differences in sunlight exposure, age and wear levels.

Whether solid or engineered, hardwood flooring is significantly easier to repair than laminate. If surface damage is extensive, the entire floor can be sanded and refinished. If damage is localized, then it can be repaired by removing and replacing individual planks, or even by manually sanding, staining and refinishing the area in question, depending on type of finish. Spot repairs are especially easy with wire brushed and oiled hardwood floors and can be done DIY-style within a couple of hours.

Ease of Maintenance

Regular sweeping, dry mopping, or wiping with a damp cloth is all that’s necessary for caring and maintaining laminate flooring. Solid and engineered hardwood floors require a little more care – they should be cleaned using special hardwood flooring cleaners (preferably manufacturer recommended ones) that preserve and restore the finish. It’s best to avoid using universal cleaners, detergents, or furniture polish – aside from making the floor finish appear greasy, they can temporarily dull, or even permanently damage the finish. Improper care practices usually void all manufacturer issued warranties.

Most hardwood floors have excellent resistance to sodas, red wine and many household chemicals. Still, in order to preserve the beauty of the floor for many years to come, it is important to quickly clean up all spills and clean the floor regularly.

Longevity

Laminate floors have a relatively short lifespan as compared to hardwood flooring. It is estimated that on average, a laminate floor will need to be replaced after no more than 20 years. Twenty years is the time it usually takes for a family to wear down the floor finish. Since laminate floors cannot be sanded or refinished, accumulated wear-and-tear, surface scratches and damages eventually destroy the floor.

Solid and engineered hardwood floors, on the other hand, can last a lifetime (40-80 years or more) if well-maintained. Once the existing finish is sufficiently worn down, the floor can be sanded and refinished. Most solid hardwood floors can be sanded up to 6-7 times, while quality engineered hardwood floors – up to 4 times. Given that the average time between sanding is 10 – 20 years, it’s easy to see how real wood floors easily outlast laminate.

Finally, when the time comes to replace the old floor, solid and engineered hardwood can be disposed (or recycled) without any damage to the environment. The same cannot be said for laminate.

Eco-friendliness

Solid hardwood floors are 100% organic as solid flooring planks are produced from single pieces of wood. Engineered hardwood is manufactured from several layers of solid wood or plywood material, also mostly organic.

Laminate floors, on the other hand, are the result of bonding various composite materials and melamine resin at high temperatures and pressure – so the floor itself is far from being organic.

Most European and North American hardwood flooring manufacturers adhere to strict industry standards, producing flooring that contains zero harmful VOC emissions and using glues that are free from formaldehyde.

During manufacture of laminate flooring, large volumes of glue are used to bond together composite material. Contents of these glues can be questionable, and it is not uncommon for cheaper toxic glues that contain formaldehyde and other harmful materials to be used. Once installed, such floors will continue to emit toxic substances into the air, affecting and threatening the health of inhabitants.

While there are high quality non-toxic laminate floors on the market, it is important to carefully research the manufacturer in order to ensure that you are buying a quality, eco-friendly product.

Reviews

By Tinky B.

By Sammy M.